Stage 1: Prepare the rosin bag

(Basic information: The lower the micron size (i.e., 25u), the smaller the holes in the bag, allowing less plant material to pass through. The higher the micron (220u), the larger the hole in the bag, allowing more plant material to pass through. Generally, larger size microns (90u-220u) are used for flowers and smaller size microns (25u-90u) are used for dry sieving /keif or bubble hashes.)

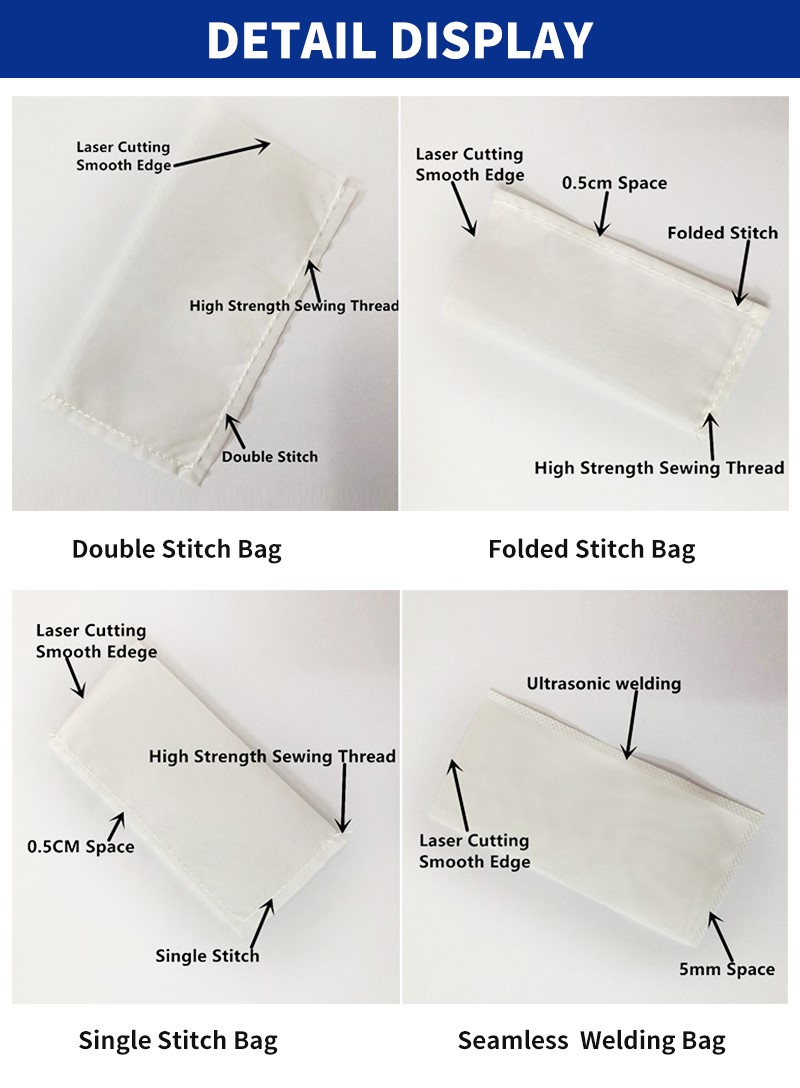

Make sure the seam of the bag is on the inside of the bag. If the thread and seam are facing the outside of the bag, the bag needs to be flipped inside out so that the seam is on the inside.

This tends to increase the overall strength of the bag under pressure and also reduces the amount of rosin that gets stuck in the seams as it flows out of the bag.

The Jingda filter bag has been pre-flipped to save you time, so if you are already using our filter bag, you can skip this step. If not, please pick them up here.

One option to prepare the bag is to use a method called Bottle Tech, which folds the bottom corner of the bag inside the bag so the corners are concave. This allows the bag to stand upright in the press, rather than flat.

Stage 2: Prepare the Cannabis Flower Material

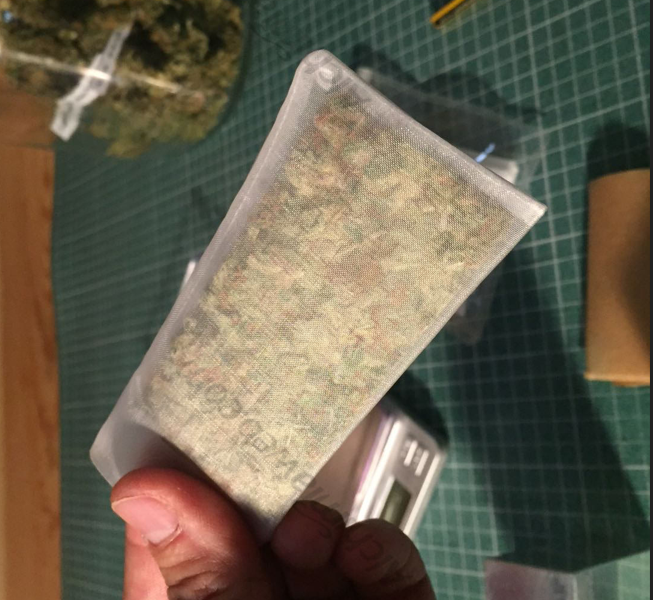

When packing the flowers by rosin filter bag, place the whole buds into the opening of the bag firstly, then push them toward the ultrasonic seal edge of the bag. You can push the bud down with your fingers or a narrow tool. We recommend using the whole bud instead of grinding your material, as the grinding process can actually agitate the trichome, and some of them can get stuck in the teeth of the grinder, reducing your overall THC content.

Keep packing until you've filled your bag. The bag should feel full, but does not matter or over packed. If you have an excess filter bag, use scissors to cut off the excess material so that the rosin does not absorb into the bag.

Once your bag is filled, we recommend the use of pre-pressing molds, different sizes of molds are suitable for a variety of hot plate and filter bag sizes. View Rosin Technology pre-press molds. This flattening technique improves production and prevents blowouts.

Once you've pre-pressed your bag and placed it between the parchment paper, you're ready to go.

Stage 3. Dry Sift and Ice Water/Bubble Hash

The method is slightly different if you use a dry sieve or ice water/bubble hash to pack your filter bag. You will need to use a spoon or funnel to insert this finer material. Slowly pour the dry sieve/hash into the bag with a spoon or funnel, making sure the material reaches the bottom of the bag and is evenly distributed throughout the bag.

Be very careful when pressing dry to sieve/hash and not overpack your bag. The bag should not feel very thick or completely full. Bags should not be more than ¼ inch thick, even before preloading. Once the material is thin and evenly spread throughout the bag, be sure to leave the ¼-½ inch filter bag empty. Fold back the excess material and "seal" the bag. For mass production, a neat little trick is to use a small amount of rosin to keep the "seal" in place. tIf the unused portion of the filter bag exceeds this length, use scissors to cut off the excess material.

Stage 4: Filling the rosin bag

Once you have your rosin material and rosin bag ready, it's time to bag it.

This stage of properly packing a rosin bag involves several steps, including filling the bag with a rosin funnel, reducing air pockets in the material, and pre-pressing.

If there are flowers in the bag, use your fingers to break up the clumps further so the material can form a solid mass inside the rosin bag.

Once the bag is full, use your fingers or a jammer-like tool to gently press the material into the bottom corners of the bag and evenly around all edges of the bag. You want to eliminate any gaps in the spacing and make sure the packaging is as consistent as possible.

Stage 5: Pre-press

After the bag is full and the material is slightly compressed, it's time to pre-press the material. Use such a precompression to quickly and thoroughly compress the material in the bag to increase the amount of rosin you can expect. Press Club has pre-pressed dies that can accommodate any size rosin bag.

Stage 6: Closing the rosin filter bag

The final step is to seal the top of the bag with a simple fold. Fold in the excess fabric at the top of the bag, this should be enough to keep the bag folded when it is between the boards.

Now that the bag is ready, grab the parchment paper and don't forget to preheat with very light pressure between the rosin pans before starting to flatten.

Our conclusion

As you can see, the process of making rosin can be quite technical, but with just a few simple steps, you can ensure an efficient press with maximum output every time. It might seem difficult at first, but that's what we're here for.

Contact: Jingda Filter Bags

Phone: +86 15100134172

E-mail: alice@jingdameshfilterbag.com

Add: No.20 Heping Road, Chang'an District, Shijiazhuang City, Hebei Province, China.